Published September 23, 2019 | By Mike Petersen

I posted to this site a tidbit about compacted soils in very moist environments as what we saw and dealt with this spring. I would like to delve into this some further to share with all of you what we observed by digging around eight different soil textures this spring in Colorado and Nebraska. It has been asked of our customers, Orthman dealers, folks at training events we carry out throughout the year, emails and phone calls “what may be limiting my row crops from getting a good start even with starter or popup fertilizers and top-of-the-line hybrids?”

Orthman 1tRIPr comparison studies

Soil compaction also called soil impedance, is quite visible when soils dry down and we can in a soil-root pit see blocked, stunted, and zig-zag roots or no roots at all below a certain depth in the upper two feet of the soil profile. Well how much soil resistance is too much for young roots in row crops to continue to extend out and away from the plant and grow downward by the pull of gravity as well as follow the moisture/warming front? It is fairly well documented in soils literature over the past 50 years (Passioura, 1991, da Silva et al., 1994, Bengough et al. 2006, Taylor and Ratcliffe, 1969) that spoil resistance above 2MPa or 290-300 pounds per square inch (psi) will essentially stop root tip extension. That is when plants are nearly mature, how about when they are young? When corn, and/or soybeans are V4 or younger? The amount of force to exert enough pressure to push roots down and into soil pores, cracks differs by crop but for simplicity, corn at 60psi, roots have a great deal of difficulty to grow. Even some of you have heard or read that roots at the root tip exude a mucous-like substance as a lubricant to alleviate some of the resistance forces to root elongation (growth). This slimy material almost like what comes from our nose only can do so much to aid root tip growth. Early in the plants life the roots are amassing length and absorptive capacity by growth down and out into the soil profile. An old mode of thought that roots were growing at the pace of the plant growing up towards the sun. Well that is not much like what really happens below the soil surface. Soil temperature, soil moisture, crop genetics have much more say in how expansive the root system will be. Gravity is a constant to help pull roots downward, that is something we can all count on. In very moist soils like what nearly every state here in USA experienced; roots were slowed by the cold soil temperatures, saturated conditions in the upper 18 inches which caused anaerobic conditions and yes, by soil density or compaction.

At Husker Harvest Days (September 10-12, 2019) we exposed to our farmers a study we did as I mentioned before. The amount of data we exposed would crowd this blog piece with columns of numbers and figures to many pages and most likely make your eyes and brain reel a bit. Others may be very intrigued. Allow me to give you a couple examples and then a summary of what we saw in 2019. We are going to study this again to capture more sites and other conditions between No-Till, Strip-Till and Broad Acre Tillage in 2020. What we did to travel between willing customers/clients across the two states, limited manpower and daylight – we saw and measured a sizable amount. So in this report I will address two very common soil textures, silty clay loam and silt loam. We will compare No-Till to Strip-Till in the silty clay loam and Conventional broad acre tillage in a silt loam soil against strip-till.

Before I move on, why did Orthman carry out such a study? Our company prides itself in having a premium Strip-Till implement to make three major strides in setting up a row crop to reach it’s potential in growth and yield: 1) A job of a top-notch seedbed, 2) alleviate compaction in the till zone for optimum root development and lastly, 3) Precision Nutrient Placement. All three of these principles demand a high quality and effective till-zone for roots to extend out and down in the soil. Water comes into the plant via roots almost wholly via the root hair surfaces (>98%). Scientists have estimated in a corn plant for instance is replacing new root hairs to the tune of 100 million per day from V9-V10 up until silking period. That is even mind boggling to me as I have looked at root systems for over 38 years having my head below ground a lot. Sorry I digressed for a moment.

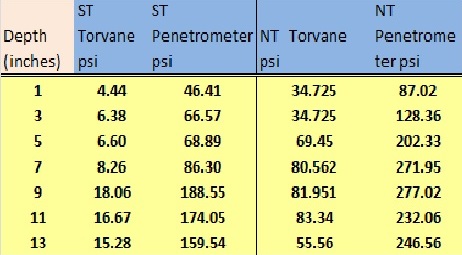

Fig. 1 StripTill -NoTill Comparison of 2019 spring conditions of silty clay loam soils. Soil resistance values right in the zone where the plant is growing after tillage/planting.

Take a look in the chart off to the left of a comparison of Strip Till (ST) and No-Till (NT). These values are from a spring strip till operation then planted and a single pass of direct seeding in silty clay loam soils. Values have been converted to psi for the Torvane shear test which reflects lateral soil resistance (left to right at specific depths) and then vertical resistance with a penetrometer as well the values are in pounds per square inch. The strip till unit (it was the Orthman 1tRIPr in this case) had positive effect to a depth of 5 to 7 inches vertically. The lateral or horizontal soil resistance shows the disturbance by the shank and wavy coulters of the 1tRIPr mellowed the soil to 7 inches. As mentioned above the 60psi level early corn roots will encounter resistance to slow or even retard root elongation and penetration. In the No Till field that was right at the 7 inch depth. Speaking with the grower he said grain cart traffic was all over the place the previous fall which most likely contributed to the density. That is apparent from the NT penetrometer readings also in Figure 1.

It is not our intention to cast stones at the No-Till system, we are reporting what we observed in a wet year and what was happening in this field. We observed in another soil texture some similar results that vertical compaction was evident below the 3 to 5 inch depth.

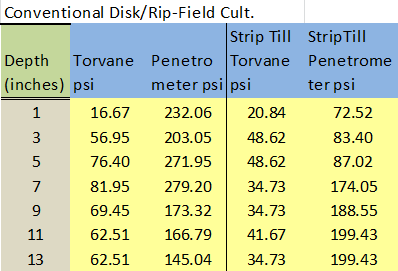

Next figure we show soil resistance values both lateral and vertically in the crop row what spring strip till with the standard point accomplishes in silt loam soils. In the conventionally full width tillage it was a pass of a disk ripper tool followed by a field cultivator then plant.

Fig.2: Silt loam soils with a comparison of conventionally tilled multiple passes to spring strip-till.

In this chart, the left two columns after the depth column are the values from the conventionally tilled field, the right two columns are the values from the Strip Tilled silt loam soils. The first 1-2 inches in the disk-rip field do have less resistance laterally. These values again are in the crop row where the corn was growing this year. Wet spring soil moisture conditions depict that the soils melt together and structural integrity is very low and the soil even when moist becomes dense. The strip till depicts lower values of 20, 48, 48, 34 psi in the first 8 inches measured by the Torvane shear testing device compared to the conventional till of 16, 57, 76,82 psi in the first 8 inches. Vertically the strip till density is approximately 60% less from the surface to 4 inches in the vertical dimension. At 7 inches where the strip till implement was pulled through the field, the soil density in 2019 is less than half of the conventionally tilled field.

Our observations depict what is happening with multiple pass tillage which has the tendency to break down soil structure, drag it, smear it and allow for oxidation of organic matter, destruction of earthworm channels and vertical root channels in the upper 8 to 10 inches. So by this kind of tillage soil structural units are damaged if not demolished. With the Orthman strip-till unit we vertically break apart the soil after a full season of re-aggregation and mix the soil in a modified U fashion on 30 or 36 inch centers in the fields we looked at and measured with the Torvane instrument and a penetrometer. We know we are tilling and mixing soil in a vertical sense about 10 inches wide at the soil surface tapered down at an approximate angle of 40-45 degrees to the points insertion depth. Our point does not create a smear pattern unless the soils are far wetter than 75% of field capacity. Growers will tell you they were out in fields wetter than that trying to dry the soils out this spring conventionally which very well set in a smear plane that may well have caused a thin barrier and inserted compaction. For many it was a gamble they said they had to take.

I will put together more charts and facts of the other sites we looked at in my next writing for you to see what other soil textures reveal with 2019’s wet soil conditions in strip till, conventional and some direct seeded corn. Now we also looked to gain more facts of where the wheel traffic was and the guess row zones can show differences. Please first digest these data sets as a taste of the rest to come. Next report will be early next week.

References used:

Bengough et al. Root responses to soil physical conditions: growth dynamics fro field to cell. Journal of Experimental Botany, 2006, Vol.57 (pg. 437-447)

daSilva et al., Characterization of the least limiting water range of soils, Soil Science Society of America Journal, 1994 vol 58 (pg.1775-1781.)

Passioura, J.B., Soil structure and plant growth., Australian Journal of Soil Research, 1991, vol.29 (pg.717-728)

Taylor HM and Ratcliffe LH, Root elongation rates of cotton and peanuts as a function of soil strength and water content, Soil Science, 1969, vol.108, (pg.113-119)